Sewer Camera Inspection in Charleston, SC

Sewer camera inspections are used throughout all phases of trenchless sewer repair at Lining Coating Solutions. This process serves as the best method for diagnosing any problem within a sewer pipeline at the onset of the investigation. During the repair phase, the sewer camera is used to confirm that portions of repairs are placed properly within a pipeline. Finally, they provide a non-invasive way to confirm that the total repair was completed properly.

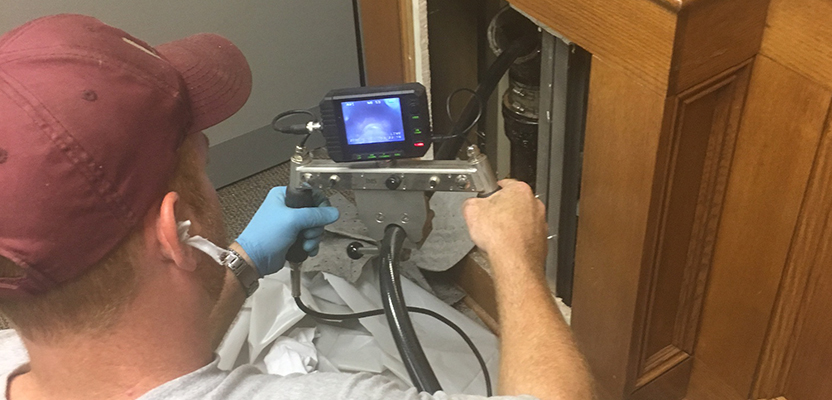

We establish a connection to the pipeline through an outside access point, such as a cleanout, and insert the our high-resolution, waterproof sewer camera into the line. The camera is navigated through the pipe with an optic cable that relays a 360-degree video recording of the interior of the pipeline wall back to a monitor for our technicians to carefully review.

If a clog or area of heavy corrosion is identified, our technicians will take the necessary steps to clean the pipes with our hydro jetting procedure. This process uses a high-pressure water hose attached to a specialized jetting head. The hydro jetting equipment scours clean the interior of the pipeline and busts through any blockage that might have collected. After the cleaning session is completed, we inspect the pipeline to confirm that the entirety of the blockage and all organic materials are completely removed. During this time, we also look for any cracks and leaks that may have been previously camouflaged by the corrosion or waste accumulation.

If our technician finds a crack in the pipeline, we recommend the trenchless sewer repair process. This process involves inserting a sleeve coated with epoxy resin into the pipeline and inflating it after it’s set in position. The resin is pressed against the interior pipe wall and held in place during the curing and hardening time. In a few hours, after the new lining has hardened, the sleeve is removed and we insert our camera into the pipeline for a final inspection to confirm that all of the trouble areas have been covered and sealed away, resulting in a new pipeline that is smooth and durable, promoting root and corrosion resistance. In addition, if we find an extensive break in the pipeline that can’t be repaired with lining services, we employ pipe bursting instead. In this repair process, a bursting head is inserted into the pipeline, moving through it and breaking it apart while pulling behind the new pipe behind it, without any extensive digging needed.

At Lining Coating Solutions, our technicians are able to accurately diagnose the problem and determine the best solution for every situation that we come across through the innovations of our sewer camera inspections. This valuable tool gives us the flexibility we need to make careful, informed decisions that will allow us to completely restore your pipes with the best methods available. Our dedicated and expert staff at Lining Coating Solutions is proud to serve the business owners across the Charleston community. Contact us to schedule a consultation and learn more how our staff can help you.